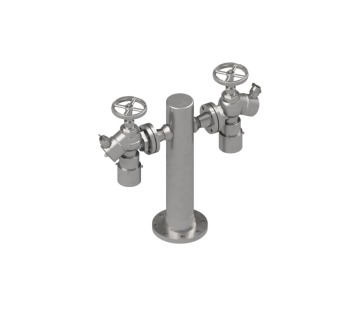

Generally installed in open deck areas, walkways, and escape routes, a Firenor firewater hydrants is the ultimate piece of firefighting equipment for manually extinguishing large and devastating fires. In addition to releasing water from a traditional water supply, a high quality Firenor firewater hydrant can also have a foam connection or integrated foam tank, allowing it efficiently deliver watermixed with foam. When used this way, the hydrant creates a blanket that extinguishes the fire by cutting off the oxygen supply to the fire, a tactic which is particularly effective against oil and fuel fires.

For optimal protection, hydrants should be placed so that any location can be reached from two separate firewater hydrants. Each hydrant consists of hoses and a nozzle that releases water at a specified flow. The nozzles can be easily opened or closed and can be adjusted to fog or jet spray. For hydrant that are supplied by a high pressure fluctuation water source, a regulating valve can be installed to avoid high reaction forces during operation. This equipment can also extinguish a pool fire by mixing foam in the water at a specified flow, should the need arise.

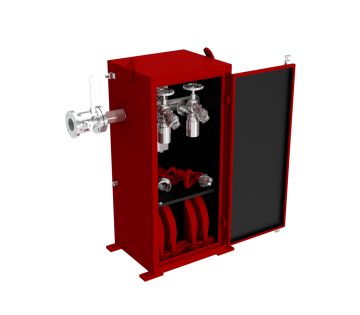

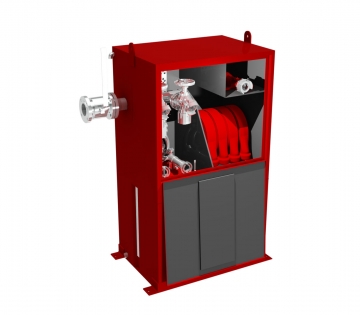

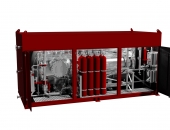

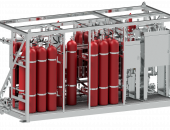

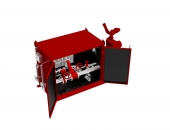

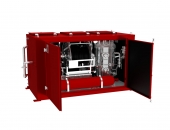

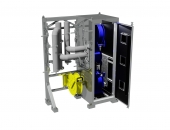

The Firenor hydrant can be customized to meet specific project requirements. As part of this customization, the Firenor hydrant can on an open frame or inside a cabinet for environmental protection purposes. Furthermore, the cabinet can be expanded beyond standard size in order to accommodate the storage of fire extinguishers and first aid kits.

Every system can be customized, upon request, for compliance with applicable rules, regulations and project specific requirements as well as standard such as CE, FM, UL, ASME, DIN, DNV, BV, NMD, IMO, NFPA, Norsok. Full documentation for any tailor-made products are available and include all necessary certifications, third party verifications such as DNV/GL, BV, ABS, etc., and full scale test reports, if required.

The foam supply for this system is provided by a central foam system. The foam can be mixed with one of solutions listed below:

- Balanced pressure foam proportioner

- Constant flow orifice

- Cabinets custom built to fully comply with customer's request.

- Firewater nozzles available in a variety of material grades up to Titanium.

- Hydrants that are DNV, BV approved upon delivery

Every Firenor system is available in the following materials:

- Galvanized carbon steel

- Copper nickel

- Super duplex

- Titanium

- Duplex

- SS316

- 6Mo

- GRE

The engineering department produces documentation relevant to all phases of the project. Documentation normally includes the following:

- Quality plan

- ITP

- Drawings

- Data sheets

- Indexes

- Procedures

- Calculations

- Certificates

- Reports

- User manual

- MRB